An Apple a Day Keeps China at Bay

With the pandemic hitting hard, major players have started shifting their supply chains from China to other countries. How? Read on.

The corona crisis has damaged China’s reputation globally, and further worsened its relations with many foreign companies. Some of these firms are now looking to move their 'supply chains' out of China (to understand what a supply chain is refer to our story here).

For almost two decades, China has been the world’s workshop: thanks to its cheap labour and favourable tax laws. Even its labour laws favour the corporates, instead of its own labourers (controversy alert!).

Note: China made the headlines for quite some time for deploying child labour (here).

The tides are now turning against them.

Various countries, including U.S, have expressed their displeasure in the way China has handled the pandemic - they believe that major losses to both lives and economies could have been prevented if China had shared some vital information earlier (oops).

Major players like Apple, Google and Microsoft had already started shifting their supply chains from China to other countries due to the US-China trade war. The pandemic has now accelerated their plans. They are eyeing countries like Vietnam, Thailand and India to diversify and de-risk their supply chains.

The Great Indian Advantage

The Virus has exposed a chink in the armour of all companies around the world. They have come to realise a costly mistake they made - putting all their eggs in one basket. That too, the Chinese basket - ‘jo chale to chand tak, nahi to shaam tak.’

Add to that the ineffective 'Intellectual Property Rights (IPR)' laws that China has (IPR laws intend to protect innovative ideas and products from being copied by others).

Plus, rising labour costs.

Damn, nothing seems to be working in their favour.

China’s pain is turning out to be India’s gain.

India 1 - 0 China.

Apple was already manufacturing some iPhone models in our country.

It is now looking to shift about one-fifth of its manufacturing capacity from China to India (one-fifth = $40bn or ₹3,00,000 crores worth of merchandise).

Wow. Pause. Breathe. Let it sink in. Now read on.

The company is also looking to take advantage of the ‘Make in India’ initiative. This initiative was started by the Government of India to attract foreign companies to set up factories in our country. This would help in increasing our employment and exports (more on this ahead).

Also, a production-linked incentives scheme (the more you produce, the more you get paid) has been recently rolled out by the government to boost domestic manufacturing and attract large scale investments in “mobile phone manufacturing and specified electronic components.” This scheme is likely to generate approximately 9,00,000 jobs over 5 years.

Note: Unemployed population in the country in Jan 2020 was estimated to be around 7.6% (~10 crore people). Apple employs 48,00,000 workers in China. Assuming 20% business shifts to India, Apple alone could generate ~10,00,000 jobs (1% of the total unemployed population). That’s huge!

Reduction in corporate tax rates, assistance to acquire land and essential infrastructure and easing of rules to do business are some other initiatives that are working in India’s favour to attract global companies to set up shop in India.

Growth Hacking

Currently, Apple sells smartphones worth about $1.5 billion in India, of which only $500 million is manufactured locally.

However, in comparison, the company produced $220 billion worth merchandise in China in 2018-19, and exported products worth $185 billion.

Of this, $40bn (or ₹3,00,000 crores worth of business) is coming our way.

($1bn = Rs. 7,500 crores).

Apple, being a tech-first company, will also bring in advanced technologies and help India start a virtuous cycle of innovation and investment from foreign companies.

Here’s how Apple could kick-start India’s growth engine.

Vocal for Local

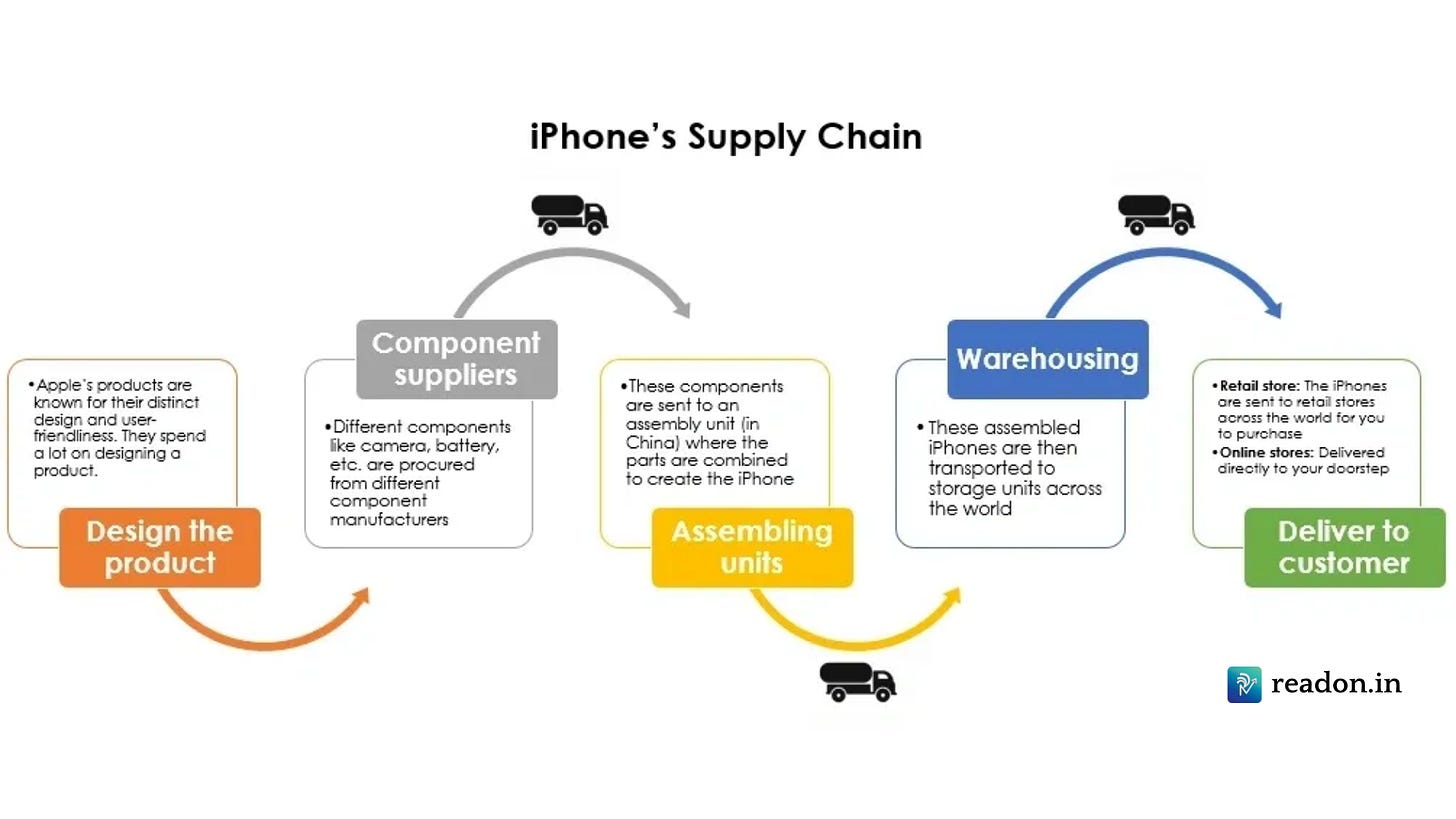

Apple’s move will set up a whole new ecosystem (a network of companies consisting of raw material suppliers, manpower recruitment agencies, assembling units, etc.) in the country. Here’s how an iPhone’s network / supply-chain / ecosystem looks like.

Various components (like battery, camera, etc.) are required to put together an iPhone.

Now, Apple can look for new suppliers in India or make its existing suppliers invest in the country. Considering that the company is obsessed about maintaining its quality, it is more likely that the existing component suppliers will also set up shop in India (until our own local companies catch up to their quality standards).

In fact, Salcomp, one of Apple’s major suppliers of mobile chargers and other components, is the first one to take lead in setting up factories in India. The company plans to invest ₹1,300 crores.

Foxconn and Pegatron are the primary assembling units for Apple in China.

Foxconn already has two assembly sites in the southern Indian states of Andhra Pradesh and Tamil Nadu, where it makes devices for Xiaomi and Nokia.

Pegatron will be the new-comer.

The smartphones will be assembled in these factories, and transported to warehouses for storage. This will mean more business for our local transportation and warehousing companies.

For getting the products to the hands of consumers, Apple plans to set up its own retail stores in the country (expected to open by 2021).

"I don't want somebody else to run the brand for us." - Tim Cook, CEO, Apple Inc.

This would mean more rent for property owners, more employment for people as sales staff, and so on.

All in all, the move will boost economic activity, and therefore, gross domestic product of the country, and take us closer to our dream of becoming a $5tn economy.

Snap Back to Reality

That’s right. All this sounds surreal.

Employment generation, more investments, higher GDP growth: all sound like promises from our favourite politician. And we know how much a politician's word is worth.

Had India been such a great destination, why did Apple (and other companies) not set up manufacturing in India from Day 1?

Well, 'experts' believe that India does not have the capabilities to support such an advanced ecosystem. The lack of skilled workforce, reliable logistics, safety and quality control standards, innovative and low-cost suppliers, infrastructure and utility services - all are a major deal breaker.

The development in these sectors is not something we can expect to happen overnight. India will take time to build such an ecosystem (it took China nearly two decades).

So, will India emerge as the global hub for manufacturing?

Will the country be able to deliver on its tall promises of development and growth?

Or, will we, once again, succumb to lethargy, bureaucracy, and policy paralysis?

We don’t have an answer, yet.

Only time will tell.

Stay tuned.

Noob’s Corner

What is Import / Export?

An "import" refers to the purchase of goods or services in your country but produced in a different country.

Imagine a port where ships are docked. When a ship comes “in” and brings goods with it, it’s called import. When the ship takes away something, we call it ex-port.

A classic example would be: Coffee beans that Starbucks coffee is made of was carefully grown and handpicked either in Guatemala or Rwanda or some other country. We import the beans. Rwanda exports it.

Import for India - purchase

Export from India - sale

Purchase implies you have to pay money, while selling something gets you money.

Think what’s better - getting money or paying money? Right. Hence, so much emphasis on increasing exports from the country.

Thousands of readers get our daily updates directly on WhatsApp! 👇 Join now!